Medical Air Regulator Group

Medical Air Regulator Group: Final Pressure Control in Air Supply Systems

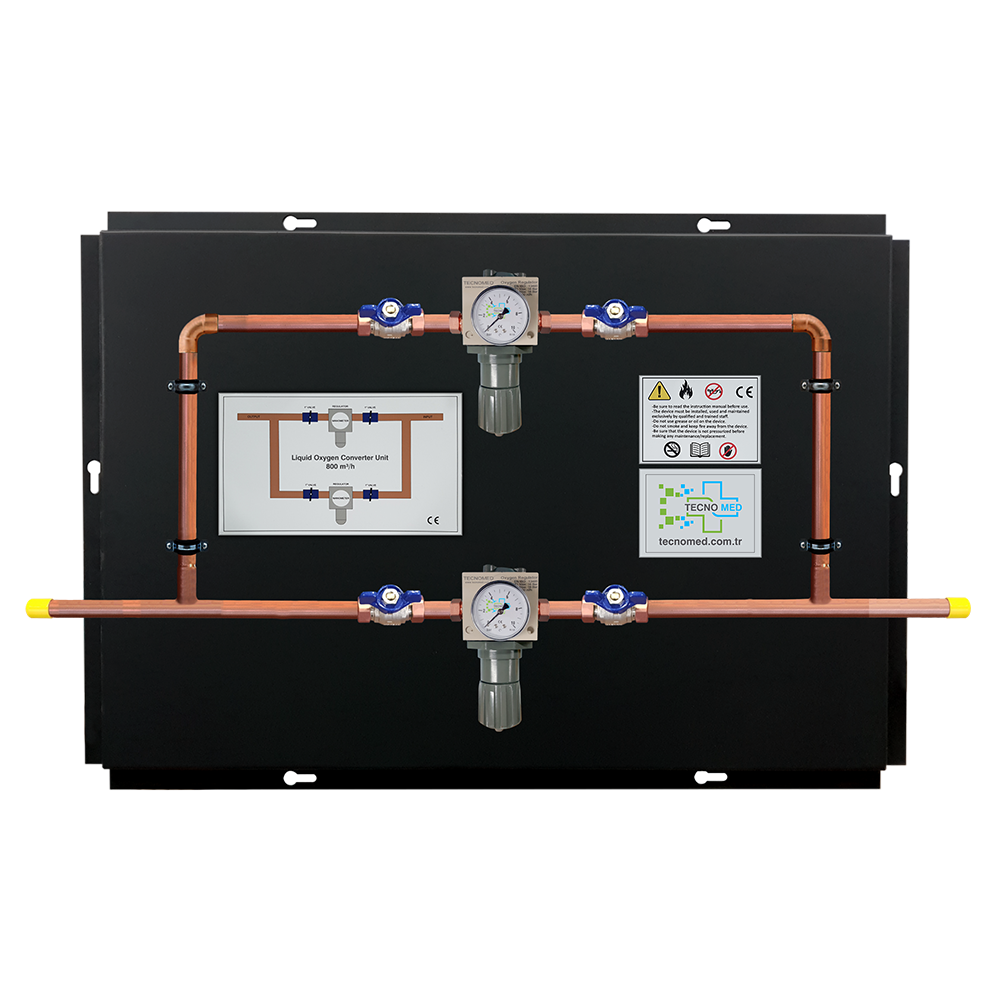

The Medical Air Regulator Group is the final component in a medical air plant, responsible for stabilizing air pressure at safe and usable levels. This unit ensures that the air delivered to patient care points and medical equipment has a constant and appropriate pressure, tailored to specific medical applications.

Proper air pressure regulation is critical in clinical environments such as intensive care units (ICUs) and operating rooms, where airflow must be both steady and safe. The regulator group guarantees this balance.

Role in Medical Air Plants

After the air is compressed, dried, and stored in tanks, it reaches the Medical Air Regulator Group, which serves as the last control barrier before entering the medical gas network.

The primary function of the unit is to stabilize pressure and control flow, adapting the system to different end uses. It ensures the air provided meets the operational needs of various hospital departments.

Pressure Range and Use Cases

Different clinical applications require different air pressures:

-

Surgical air systems typically require 7–8 bar pressure to power pneumatic tools and ventilation systems used in operating rooms.

-

Respiration air supply in ICUs and operating rooms uses a reduced range of 4–5 bar, which is suitable for patient breathing and anesthesia equipment.

By offering adjustable regulation, the Medical Air Regulator Group adapts to both of these use cases without compromising air quality or flow consistency.

Installation and Operation

The unit is typically mounted close to the final air distribution point. It works in tandem with valves, gauges, and outlet fittings to ensure precise regulation.

Once installed, it performs its role passively, needing only periodic checks to verify pressure levels. The regulator is factory-calibrated to ensure consistent pressure delivery in accordance with the selected application.

Safety and Stability

In medical air systems, even small fluctuations in pressure can affect equipment accuracy and patient safety. The Medical Air Regulator Group prevents pressure spikes and drops by offering controlled, gradual transitions between system conditions.

Stable air delivery protects sensitive devices from damage and guarantees continuous respiratory support in critical care situations.

Medical Environments Where It’s Used

The Medical Air Regulator Group is essential in:

-

Operating rooms

-

ICU and neonatal care units

-

Anesthesia departments

-

Mechanical ventilation systems

-

Emergency response units

Its ability to serve multiple functions through one regulated outlet makes it a flexible and indispensable part of modern hospital infrastructure.

Key Features of the Medical Air Regulator Group

-

Final component in medical air plant systems

-

Stabilizes pressure before distribution

-

Supports 7–8 bar for surgical air and 4–5 bar for ICU respiration

-

Provides steady and accurate air flow

-

Compatible with various medical devices

-

Easy to monitor and maintain

-

Ensures system safety and performance reliability

Conclusion

The Medical Air Regulator Group by Tecnomed plays a critical role in maintaining pressure stability in compressed air systems. With specific ranges for surgical and respiratory use, it enables hospitals to deliver accurate and safe airflow where it matters most.

Its compact design, passive operation, and application flexibility make it an essential part of any modern medical air infrastructure.

Our Contact Information

Contact

+90 212 909 0484

Address

İkitelli Osb. Metal iş Sanayi Sitesi 19.Blok No:40 Başakşehir İSTANBUL-TÜRKİYE

E-Mail

info@tecnomed.com.tr

sales@tecnomed.com.tr

Most Searched

Bed Head Unit, Intensive Care Unit, Manifold System, Medical Flowmeter, Medical Gas, Medical Gas Outlet, Medical Gas Socket, Medical Gas Terminal, Medical Gas Systems, Medical Pendant, Medikal Gaz, Operating Room Pendant, Oxygen Flowmeter, Oxygen Manifold System, Oxygen Outlet, Oxygen Terminal, Suction Regulator, Surgical Pendant

Tecnomed Copyright © 2024 All rights reserved.