Medical Air Plant

Medical Air Plant: Production of Sterile Air for Healthcare Facilities

The Medical Air Plant is a complete system that enables the generation and delivery of sterile compressed air required in hospitals and medical centers. It plays a crucial role in supporting surgical units, intensive care environments, and respiratory applications where air purity is essential.

Tecnomed’s solution ensures clean, stable and pressurized air output suitable for medical use.

System Components and Structure

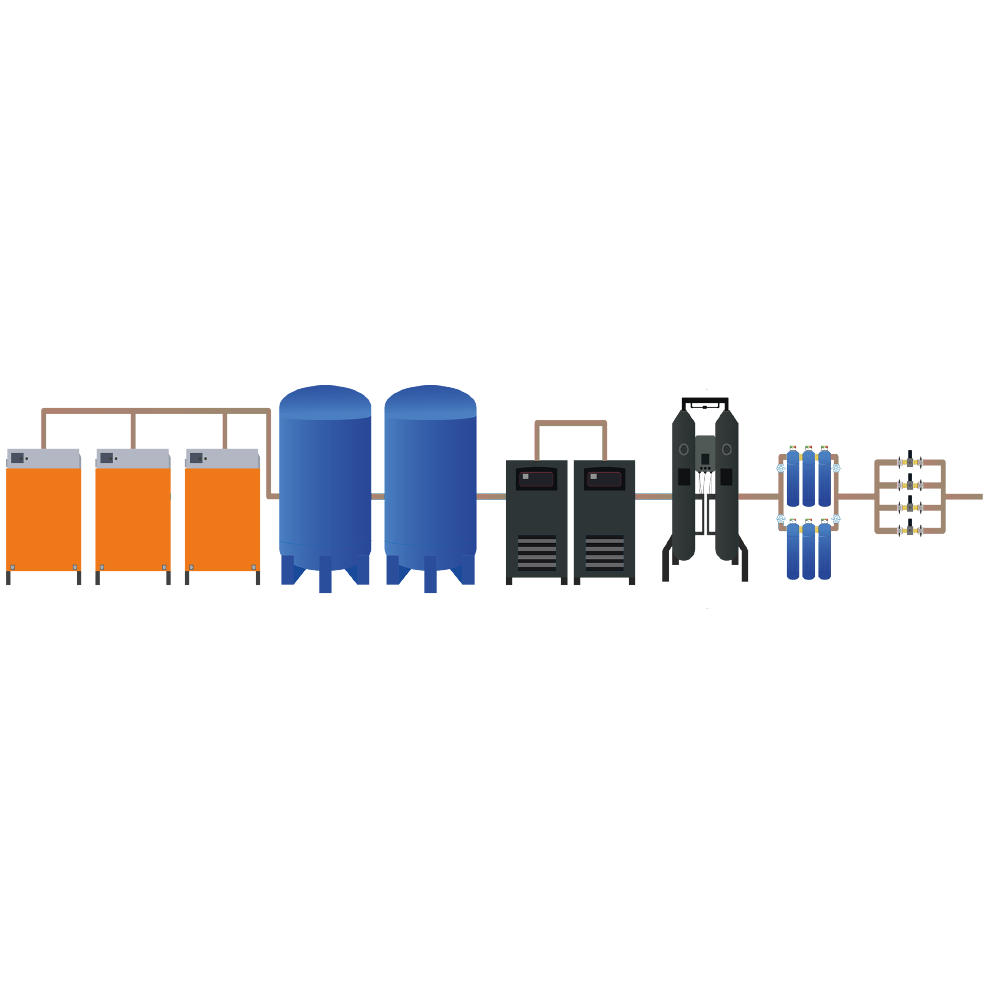

A typical Medical Air Plant consists of the following integrated units:

-

Screw Air Compressors

-

Compressed Air Storage Tanks

-

Physical and Chemical Dryers

-

Compressed Air Filters

-

Medical Air Regulator Panel

These components work in sequence to compress, dry, purify, and regulate the air before it is delivered to the hospital’s pipeline system.

Working Principle and Pressure Range

The process begins with screw air compressors, which compress ambient air and send it to the pipeline. The compressed air pressure ranges between 7 and 10 bar, depending on the output pressure of the compressor.

This air is then sent to storage tanks, which act as a buffer and stabilize the flow. From there, it passes through dryers—both physical and chemical types—to eliminate moisture, which can cause corrosion and bacterial growth.

After drying, the air enters compressed air filters, where particles and oil residues are removed. Finally, the air reaches the regulator panel, which stabilizes the pressure for safe delivery to medical equipment and end points.

Medical Application Areas

Medical Air Plants are used across a wide variety of departments and medical scenarios, including:

-

Operating rooms

-

Intensive care units (ICU)

-

Neonatal care

-

Respiratory treatment areas

-

Dental and endoscopic systems

The production of medical air must meet strict hygiene and pressure standards, and the Tecnomed system is designed to support compliance with these needs.

Reliable and Modular Configuration

Tecnomed’s Medical Air Plant systems are built with modularity in mind. Hospitals can scale the system according to their capacity and infrastructure. Components such as compressors, dryers, or filters can be upgraded or duplicated for redundancy.

This flexibility ensures that facilities can maintain air supply even during equipment maintenance or emergency demand increases.

Safety and Quality

Each stage of the Medical Air Plant is optimized to reduce risks associated with unfiltered or humid air. By eliminating moisture and contaminants, the system ensures safe delivery of air to patients.

The use of a medical air regulator panel ensures pressure remains within the required range for respiratory equipment and pneumatic medical tools.

Key Features of the Medical Air Plant

-

Produces sterile compressed air for hospital systems

-

Includes compressors, tanks, dryers, filters, and regulators

-

Output pressure range: 7–10 bar

-

Modular design for system scalability

-

Designed for high-purity air delivery

-

Suitable for multiple clinical applications

-

Reduces moisture and contamination risk

Conclusion

Tecnomed’s Medical Air Plant is an integrated and reliable solution for hospitals requiring a continuous supply of sterile, pressurized air. With a complete set of components from compressors to regulators, the system delivers hygienic, dry, and stable airflow for critical medical procedures.

Its pressure range of 7–10 bar and modular flexibility make it ideal for healthcare environments of all sizes.

Our Contact Information

Contact

+90 212 909 0484

Address

İkitelli Osb. Metal iş Sanayi Sitesi 19.Blok No:40 Başakşehir İSTANBUL-TÜRKİYE

E-Mail

info@tecnomed.com.tr

sales@tecnomed.com.tr

Most Searched

Bed Head Unit, Intensive Care Unit, Manifold System, Medical Flowmeter, Medical Gas, Medical Gas Outlet, Medical Gas Socket, Medical Gas Terminal, Medical Gas Systems, Medical Pendant, Medikal Gaz, Operating Room Pendant, Oxygen Flowmeter, Oxygen Manifold System, Oxygen Outlet, Oxygen Terminal, Suction Regulator, Surgical Pendant

Tecnomed Copyright © 2024 All rights reserved.